Optimizing Heat Exchanger Performance: A Comparative Analysis of Flowing and Cooling Fluids using Numerical Simulations

Keywords:

Computational Fluid Dynamics, heat exchanger, heat transfer, working fluid, numerical simulation, SolidWorks Flow Simulation, thermal efficiencyAbstract

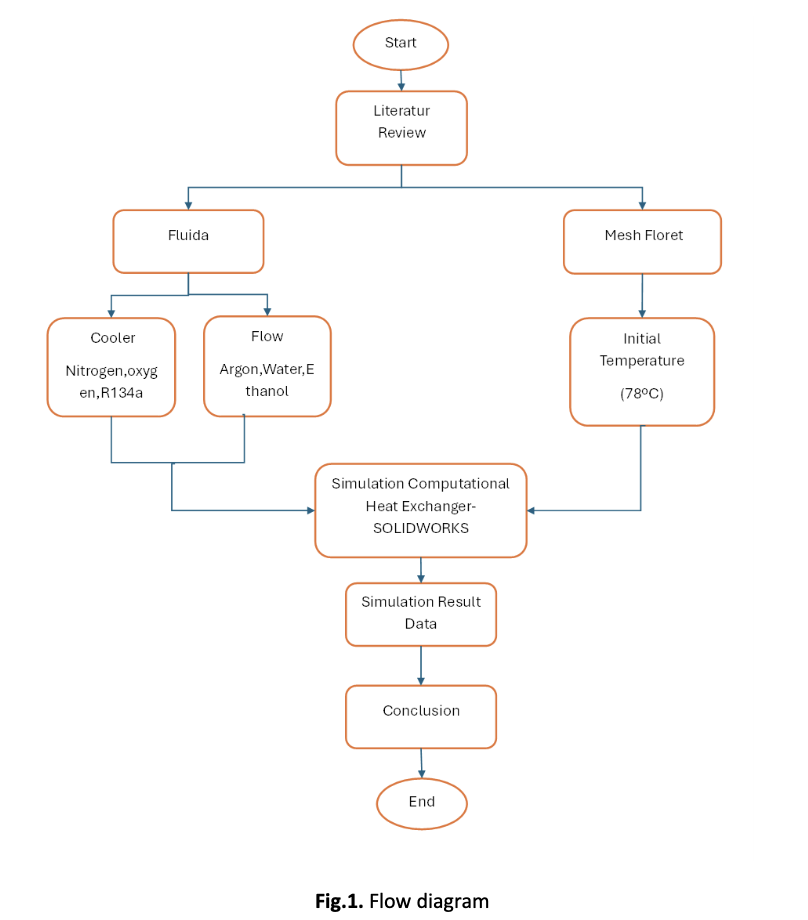

Heat exchangers are one of the main devices in heat transfer systems that are widely used in industries such as power plants, chemical processes, and cooling systems. The performance of heat exchangers is greatly influenced by the thermophysical properties of the fluids used, both as hot-side working fluids and cold-side coolant fluids. This study uses a SolidWorks Flow Simulation-based numerical simulation method to analyze the differences in heat exchanger performance with variations in three flowing fluids (water, ethanol, argon) and three cooling fluids (nitrogen, oxygen, R134a) at an initial temperature of 78 °C. The simulation results show significant differences in the average temperature of each fluid. Water proved to be the most effective flowing fluid with an average temperature of 48.04 °C, while R134a was the most optimal cooling fluid with an average temperature of 36.29 °C. The combination of these two fluids provides the best heat transfer performance, making them the ideal pair for improving heat exchanger system efficiency. These findings emphasize the importance of selecting the right fluid to support the reliability and efficiency of industrial applications.